Laser cleaning method is more and more popular in the past few years compare to other traditional cleaning method such as dry ice cleaner, chemical cleaner, mechanical grinding machine and ultrasonic cleaner. Because laser cleaner have many advantages such as non-contact process, no damage to the base material, high cleaning efficiency and high cleanliness, precise controllable and high precision, no pollution exsiting during cleaning, easy operation of laser cleaner, low consumables & low runing cost.

In laser cleaning machine, there are 2 types: pulsed laser cleaner & continuous laser cleaner, which adopts different fiber laser source. Commonly handheld type pulsed laser cleaner have laser power 100w, 200w, 300w, 500w & 1000w for optional, and the handheld type continuous laser cleaner have laser power 1000w, 1500w, 2000w & 3000w for optional

For rust removal by laser, after lots of cleaning comparison, the continuous laser cleaner have big advantage in cleaning efficiency compare to pulsed laser cleaner, so lots of rust remvoal jobs can be handled by continuous laser cleaning machine, the laser power we recommend at least 1500w. Also continuous laser cleaning machine has advantage in price, will pay less money in purchase continuous laser cleaning machine compare to pulsed laser cleaning machine

Here we will do the comparison between pulsed laser cleaner & continuous laser cleaner major in painting removal or coating removal, especially in cleaning speed, cleaning affection, the affact to the base material, cleaning roughless

.

The energy of pulsed laser is stored and released periodically, high peak intensity, which determine the high efficiency in painting removal by pulsed laser cleaner

We compare between 100w pulsed laser cleaner and 1000w continuous laser cleaner. The leaning efficiency for paint removal on aluminum surface, it is much higher 7.7 times than that of continuous laser. The cleaning efficiency of pulsed laser is 2.77m2/h, while the continuous laser is 0.36m2/h. And the cleaning efficiency for paint removal on carbon steel is 3.5 times than that of continuous laser. The efficiency laser is 1.06m2/h, while the cleaning efficiency of continuous laser is 0.3m2/h

The surface aluminum after laser cleaning, left side one is cleaned by pulse fiber laser, we can see paint on the surface has been completely removed, and there is little damaged and no laser lines; right side one is done by continuous fiber laser, the paint was also completely removed, but there was a serious remelting phenomenon on the surface, and laser lines appeared;

It's shown the comparison of painting removal on carbon steel by pulsed laser & continuous laser, the left side one is made by pulse laser, the surface is relatively smooth; And the right side one is made by continuous fiber laser, the paint was also completely removed, but the surface was remelted seriously, and the surface was uneven.

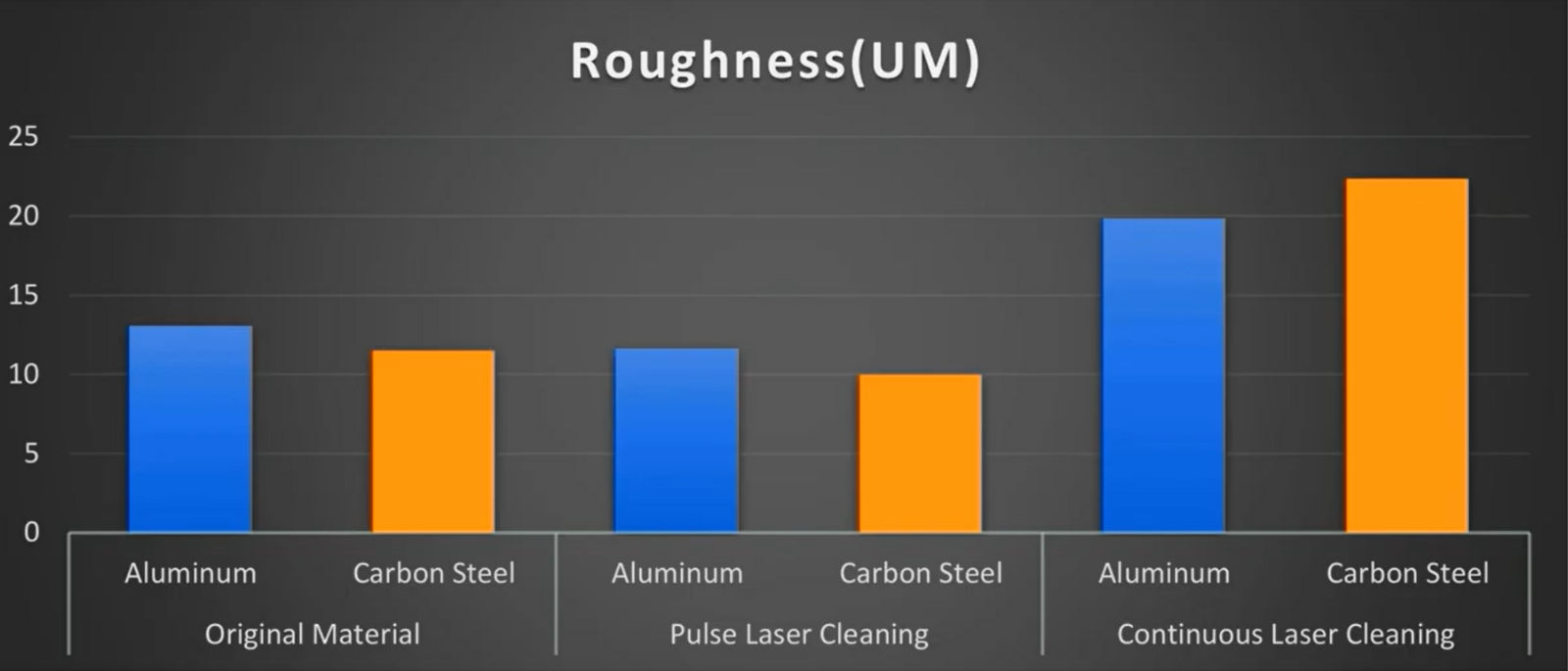

The pulsed laser damages the surface less, which the surface roughness after cleaning is close to that of the original materials. But after continuous laser cleaning, the damage to the surface is greater, so the surface roughness is 1.5 times the roughness of the original material and 1.7 times the surface roughness after pulsed laser cleaning.

Pulsed lasers can better control the heat input to prevent excessive substrate temperature or micro-melting, so that the pulse laser cleaning will lead to less damage to the base metal plates compared with continuous laser cleaning. Pulsed laser have high precision and strict heating control, which requires the substrate to be non-destructive, such as molds. Can get more beautiful cleaning results, better surface finish such as paint removal

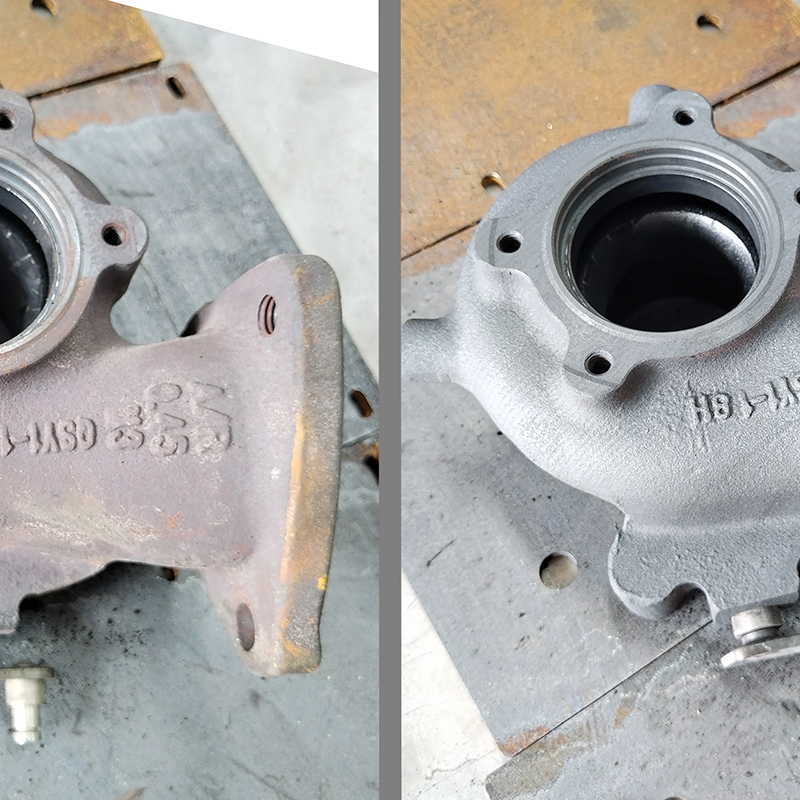

Pulsed lasers working on the auto parts cleaning

Pulsed lasers working on molds cleaning industry

Pulsed lasers working on repair of monuments, cultural heritage and general restoration

info@fivelaser.com

info@fivelaser.com